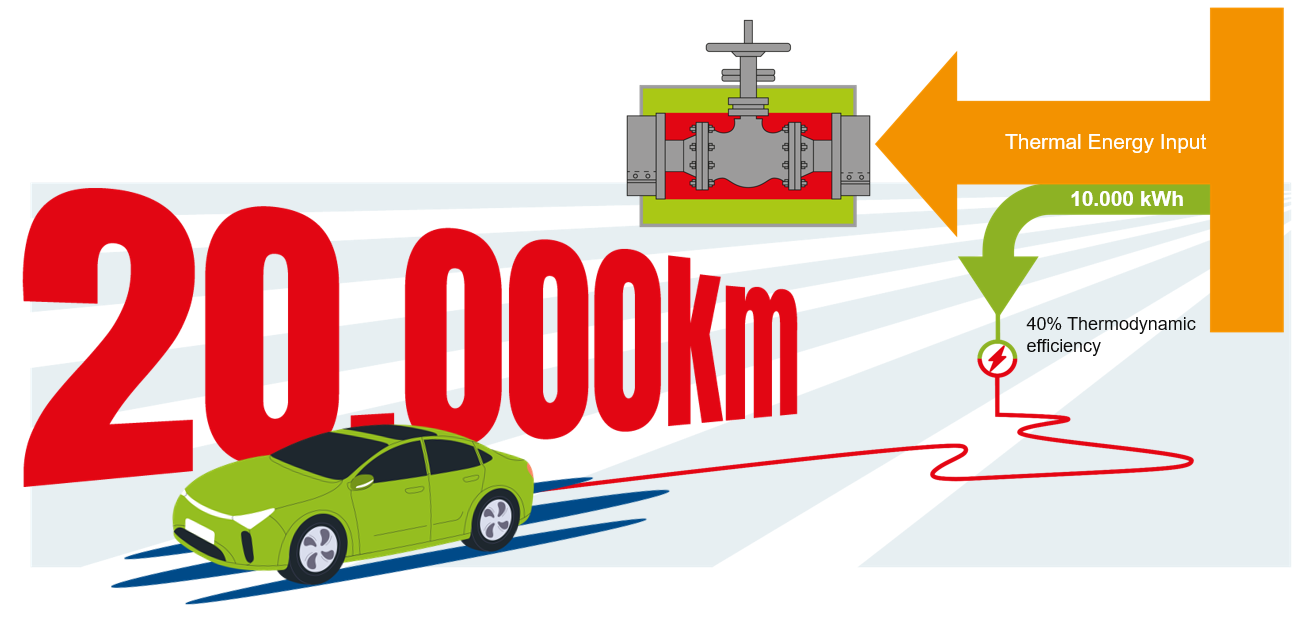

Insulating ONE valve drives an electric car 20.000 km

Industrial processes are energy intensive

To keep process temperatures in industry at high levels

(up to 600 °C and more), an intensive energy input to the

system is needed. High temperatures lead to high heat

losses on uninsulated equipment adding to an intensive

energy consumption of the system.

Typically uninsulated equipment

The TIPCHECK thermal energy audit experience shows

that valves and flanges in industrial plants are typically

uninsulated. The energy loss can be detected and

illustrated with infrared thermography.

One uninsulated valve

Size: DN 150/6 inch

Temperature: 150 °C

Operational time: all year (8.760 hours)

Annual energy loss: 10.600 kWh

By insulating the valve 10.000 kWh can be saved

Transforming the saved 10.000 kWh thermal energy with a 40% thermodynamic efficiency into 4.000 kWh electric energy and using this to charge the battery of an electric car, one could drive more than 20.000 km.